At Modern Bee Farmers, we’ve been working with Kenyan beekeepers since 2007, and one thing has remained constant: beeswax in Kenya is one of the most valuable and underutilized products from the hive. While most beekeepers focus solely on honey production, beeswax offers significant income potential, especially when properly harvested, processed, and marketed.

This guide explains how beeswax is produced in Kenyan hives, the methods local beekeepers use to harvest and refine it, the growing demand both locally and internationally, and realistic price ranges based on what we see in the Kenyan market today.

What Is Beeswax and How Is It Produced in Kenyan Hives?

Beeswax is a natural wax produced by honeybees to build the comb structure inside their hives. Worker bees secrete wax from special glands on their abdomens when they’re between 12 and 18 days old. They use this wax to construct hexagonal cells for storing honey, pollen, and raising brood.

In Kenya, beekeepers primarily use three types of hives:

- Langstroth hives (the most common modern hive, with removable frames)

- Kenya Top Bar Hives (KTBH) (popular among small-scale beekeepers)

- Traditional log hives (mostly used in rural areas)

Regardless of the hive type, bees build comb using the same natural process. The difference lies in how easily beekeepers can harvest that wax.

In Langstroth hives with foundation sheets, bees build comb on pre-formed wax sheets, making harvesting more controlled. In top bar and log hives, bees build natural comb that hangs from bars or the hive roof, which often contains more wax per harvest since there’s no pre-existing foundation to limit comb building.

A single Langstroth hive can produce between 0.5 to 1.5 kilograms of beeswax per year, depending on colony strength, forage availability, and how often the beekeeper harvests. Top bar hives typically yield slightly more wax because beekeepers often crush and strain the entire comb during honey extraction, releasing more wax than the cappings-only method used with framed hives.

Step-by-Step: How Kenyan Beekeepers Harvest and Process Beeswax

Based on 17+ years of supplying Kenyan beekeepers, we’ve observed that wax harvesting methods vary widely depending on equipment availability and scale of operation. Here’s the typical process:

1. Wax Collection During Honey Harvest

Most beeswax is obtained as a byproduct of honey extraction. When beekeepers remove honey, they get wax in three main ways:

- Cappings: The thin wax layer sealing honey cells (cleanest wax source)

- Old/damaged comb: Dark comb that needs replacing

- Burr comb: Excess wax bees build between frames or bars

2. Initial Cleaning

After collection, beekeepers remove visible debris, dead bees, cocoons, propolis, and dirt. Many soak the wax in cold water for a day or two, which helps separate some impurities.

3. Melting the Wax

Beekeepers use several melting methods:

- Solar wax melters: Simple, cost-free, popular in sunny areas like Machakos and Laikipia

- Double boiler method: Melting wax in a container placed inside boiling water (safest controlled method)

- Direct heat: Used by most, but risky, wax can catch fire above 200°C

At Modern Bee Farmers, we always advise the double boiler method for small-scale processing. It’s safer and produces cleaner wax.

4. Filtering

Once melted, the wax is poured through cloth (old t-shirts work well) or fine mesh sieves to remove particles. We usually filter twice for higher quality wax.

5. Cooling and Molding

The filtered wax is poured into molds, sometimes old cooking oil containers, bowls, or purpose-made molds. As it cools, impurities rise to the top or sink to the bottom, making it easy to scrape them off once the wax solidifies.

6. Final Refining (Optional)

For premium-grade wax, we remelt and refilter several times, or add a small amount of water during the melt to help separate the finest impurities.

Local Demand: Where & How Beeswax Is Used in Kenya

Kenya has diverse local markets for beeswax, both traditional and industrial. Understanding these markets helps beekeepers position their product effectively.

1. Cosmetics and Personal Care Products

The natural cosmetics industry in Kenya is growing rapidly. Beeswax is a key ingredient in:

- Lip balms and lipsticks

- Hand creams and lotions

- Hair pomades and styling products

- Soap making (natural, artisan soaps)

Small cosmetic makers in Nairobi, Nakuru, and Mombasa actively seek locally sourced beeswax. This market typically pays premium prices for refined, light-colored wax.

2. Batik and Textile Arts

Kenya’s vibrant textile industry, especially batik fabric production, uses beeswax as a resist agent. Artists apply hot wax to fabric before dyeing, creating intricate patterns. Coastal regions and art centers have steady demand for affordable, mid-grade beeswax.

3. Candle Making

Both commercial and artisan candle makers use beeswax. Natural beeswax candles:

- Burn longer and cleaner than paraffin candles

- Emit a subtle honey scent

- Are increasingly popular in hotels, churches, and homes

At Modern Bee Farmers, our beeswax candles range from small pillars to decorative shapes, reflecting the local demand for ready-made wax products.

4. Wood Polish and Leather Care

Traditional furniture makers and leather craftsmen use beeswax to create natural polishes and conditioners. Mixing beeswax with oils produces effective, chemical-free wood treatments popular among woodworkers in Nairobi and Kisumu.

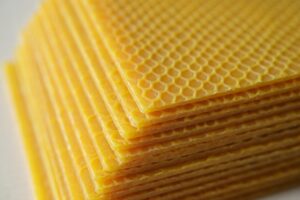

5. Foundation Sheets for Beekeeping

This is perhaps the most critical local use. Foundation sheets—thin wax sheets pressed with hexagonal cell patterns—are placed in hive frames to guide bees in building straight comb. At Modern Bee Farmers, we sell foundation sheets at KSh 180 per sheet, and the demand is constant.

Manufacturing foundation requires specialized equipment (embossing rollers), so most Kenyan foundation is either imported or produced by a handful of local processors. Beekeepers selling bulk wax to foundation manufacturers get consistent buyers but typically receive lower prices than retail markets.

International Demand and Export Potential

Kenya exports modest quantities of beeswax, primarily to Europe and Asia. The international market values:

- Light-colored, refined wax

- Organic-certified wax

- Consistent supply

However, most small-scale Kenyan beekeepers don’t export directly. Instead, they sell to local aggregators or processors who then export. Challenges include:

- Certification costs (organic certification, export permits)

- Quality consistency requirements

- Lack of aggregation infrastructure

That said, there’s untapped potential. Organizations like ICIPE (International Centre of Insect Physiology and Ecology) have documented Kenya’s capacity to increase beeswax exports significantly if quality and supply chain issues are addressed.

Current Beeswax Prices in Kenya.

Beeswax prices in Kenya vary widely based on quality, quantity, location, and buyer type. Here’s what we’ve observed in the market:

Raw, Unprocessed Beeswax

- Small quantities (under 5kg): KSh 400–700 per kg

- Bulk quantities (20kg+): KSh 300–500 per kg

This is wax straight from the hive, containing impurities, dark color, often with propolis mixed in. Buyers are typically local processors or intermediaries.

Filtered, Block Beeswax

- Retail (1–5kg): KSh 800–1,500 per kg

- Bulk (10kg+): KSh 600–900 per kg

This is the refined product most beekeepers can achieve with basic filtering. At Modern Bee Farmers, we sell 1kg beeswax blocks at KSh 1,100, which reflects the retail market rate for quality, filtered wax.

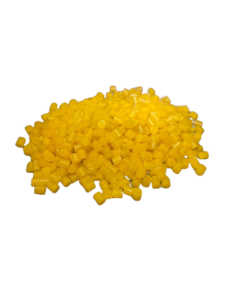

Premium Pellets (Cosmetic Grade)

- Retail: KSh 1,400–1,600 per kg

Pellets are convenient for cosmetic makers and candle makers because they melt quickly and measure easily. At Modern Bee Farmers, we offer:

- 1kg beeswax pellets at KSh 1,500

- 500g pellets at KSh 800

- 200g pellets at KSh 450

This pricing reflects the added value of pelletizing (specialized equipment and labor) and the convenience factor for end users.

Value-Added Products

- Beeswax candles: KSh 100–500+ depending on size

- Foundation sheets: KSh 180 per sheet

- Cosmetic products (lip balms, etc.): KSh 200–800 depending on the product

The price difference between raw wax (KSh 400/kg) and pellets (KSh 1,500/kg) shows the value addition potential. A beekeeper who processes wax into pellets can nearly triple their income compared to selling raw wax to intermediaries.

How Small-Scale Beekeepers Can Add Value to Beeswax

Most beekeepers sell raw wax because they lack processing knowledge or equipment. Here’s how to move up the value chain:

Step 1: Improve Cleaning and Filtering

Simply filtering wax twice instead of once can increase your selling price by 30–50%. Light-colored, clean wax fetches premium rates.

Investment needed: Minimal, cloth filters, pots, heat source (KSh 2,000–5,000)

Step 2: Mold into Uniform Blocks

Instead of selling irregular chunks, pour wax into uniform 1kg blocks. Buyers (especially cosmetic makers) prefer standardized weights.

Investment needed: Basic molds (KSh 500–2,000)

Step 3: Target Direct Buyers

Skip intermediaries. Sell directly to:

- Cosmetic makers

- Candle makers

- Batik artists

Investment needed: Time and marketing

Step 4: Form Cooperatives

Pooling wax from multiple beekeepers allows bulk processing and better negotiation power with buyers. Some of the most successful beekeeping groups in Baringo, Kitui, and Laikipia follow this model.

Step 5: Create Simple Value-Added Products

If you have basic skills, consider:

- Rolling beeswax candles (requires minimal equipment)

- Making simple lip balms (requires oils, containers, basic training)

- Producing wood polish (beeswax + oil blends)

These products can earn 5–10 times more than raw wax per kilogram.

Where Modern Bee Farmers Fits In

At Modern Bee Farmers, we support Kenya’s beekeeping value chain in three ways:

1. We Supply Inputs

Beekeepers need quality foundation sheets to produce clean, harvestable comb. Our wax foundation sheets (KSh 180 each) help beekeepers maximize both honey and wax yields by giving bees a head start in comb building.

2. We Process and Sell Beeswax Products

For beekeepers who lack time or equipment to process wax themselves, we offer a market outlet. We also supply processed beeswax products to end users:

- Beeswax blocks (1kg at KSh 1,100)

- Beeswax pellets (1kg at KSh 1,500, 500g at KSh 800, 200g at KSh 450)

- Ready-made beeswax candles

This means cosmetic makers, candle makers, and crafters can buy from us, while beekeepers can see what the retail market looks like and plan their own value addition strategies accordingly.

3. We Provide Knowledge and Support

Through articles like this, product demonstrations at our shop, and conversations with customers, we share practical beekeeping and processing knowledge gained from 17+ years in the industry.

The Future of Beeswax Production in Kenya

Beeswax remains an underexploited resource in Kenyan beekeeping. Most beekeepers earn less than KSh 500 per kilogram selling raw wax to intermediaries, yet the same wax, properly processed, can retail for KSh 1,500+ per kilogram.

The opportunity is clear:

- Process your wax properly—filtering and molding adds immediate value

- Target direct buyers—cosmetic makers, crafters, and candle makers pay better prices

- Consider value addition—even simple products like candles multiply income

- Aggregate for scale—cooperatives can negotiate better prices and invest in shared equipment

The local market for beeswax in Kenya is growing. As natural cosmetics gain popularity, as artisan crafts expand, and as more beekeepers discover wax’s income potential, demand will continue to rise.

At Modern Bee Farmers, we’ve seen this shift firsthand. When we started in 2007, beeswax was almost an afterthought. Today, it’s a critical product line, for us, for beekeepers, and for the diverse industries that depend on this remarkable natural material.

If you’re producing beeswax and want to understand the market better, visit our shop in Nairobi, explore our product range (including our beeswax blocks and pellets), and see what professional processing looks like. The knowledge you gain will translate directly into better income from your hives.