Choosing the right honey harvesting equipment is one of the most important decisions facing Kenyan beekeepers today. Whether you manage a few hives in rural Kenya or run a commercial operation near Nairobi, the choice between a honey press and a honey extractor machine will affect your productivity, honey quality, labor requirements, and long-term profitability.

The decision isn’t simply about cost. It depends on the type of hives you use, how much honey you harvest, whether you want to preserve your comb for reuse, and how you plan to scale your beekeeping operation. Langstroth hive owners typically favor centrifugal honey extractors, while Kenya Top Bar Hive (KTBH) beekeepers often find a honey press more practical for their natural comb harvesting.

This guide will help you understand both methods, compare their advantages and limitations, and make an informed choice based on your specific situation in Kenya.

How a Honey Extractor Machine Works (Centrifugal Method)

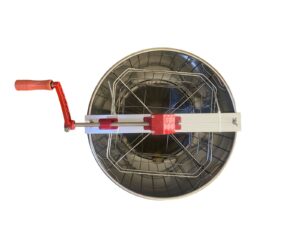

A honey extractor machine uses centrifugal force to remove honey from capped honeycomb while keeping the wax comb structure intact.

The process is straightforward: after uncapping the sealed cells with a decapping fork or knife, you place the frames inside the extractor drum. As you manually crank the handle (or turn on the electric motor), the frames spin rapidly. The spinning motion forces honey out of the cells and against the extractor’s inner walls, where it drips down to a collection area at the bottom.

You then open the honey gate valve to drain the liquid honey into food-grade buckets or settling tanks.

This method is specifically designed for Langstroth hive frames, which have bees wax foundations that hold the comb structure firm during extraction. In Kenya, Langstroth hives are widely used by both small-scale and commercial beekeepers because they allow for standardized frame management and easier hive inspections.

Modern Bee Farmers offers several honey extractor machine options to match different operation sizes.

Our 2-frame manual extractor works well for beekeepers starting out or managing fewer than 10 hives.

The 3-frame model provides faster processing for growing apiaries. For those ready to scale up,

The 4-frame manual extractor handles larger batches efficiently, while the 4-frame electric extractor eliminates the physical effort of cranking, making it ideal for commercial operations or beekeepers processing honey regularly throughout the season

Advantages of a Honey Extractor Machine

The primary benefit of using a honey extractor machine is comb preservation. After extraction, frames still contain intact comb that bees can immediately refill with nectar. This saves your colony weeks of work and significant energy, bees consume approximately 8 kilograms of honey to produce just 1 kilogram of wax. By reusing comb, you reduce the time between harvests and increase your annual honey yield without adding more hives.

Centrifugal extraction is also notably faster than pressing, especially when you’re processing multiple frames. Once you establish a rhythm like we have, from uncapping, spinning, draining, you can process dozens of frames in a single afternoon. This speed becomes essential during Kenya’s main honey flow periods when timing matters.

The honey produced through centrifugal extraction tends to be cleaner with less debris. While you’ll still need to strain the honey through a double sieve to remove fine pollen particles and any small wax fragments, there’s significantly less wax contamination compared to crush-and-press methods. This results in a clearer, more market-ready product.

For beekeepers planning to scale beyond 15-20 hives, a honey extractor machine becomes increasingly practical. The investment pays off through faster processing, better honey quality, and the ability to harvest more frequently throughout the year. The system integrates well with other honey processing equipment, decapping tools remove the wax caps, the extractor removes the honey, settling tanks allow debris to rise, and food-grade storage buckets keep your honey safe until bottling.

Limitations of a Honey Extractor Machine

A honey extractor machine requires well-constructed Langstroth frames with proper foundation and wiring. Frames that aren’t built correctly may collapse under centrifugal force, especially when filled with heavy honey. This means you need quality frames from the start and proper frame maintenance throughout the season.

The upfront investment is higher compared to a honey press. The entry-level 2-frame manual extractor costs the same as the basic press, and you’ll need additional equipment to complete your honey extraction system: a decapping fork or knife, strainers, food-grade buckets, and potentially settling tanks. These supporting tools add to the initial outlay, though they represent a one-time investment that serves you for years.

The system also requires more physical space than pressing. You need room for the extractor itself, an uncapping station, buckets or tanks for collection, and a clean working area. For beekeepers with limited space or those harvesting in remote locations without electricity (for the electric models), the larger footprint and dependency on having everything set up properly can present challenges.

Heading How a Honey Press Works (Crush-and-Press Method)

A honey press uses a fundamentally different approach: it crushes honeycomb and applies direct pressure to squeeze out the honey. You place sections of natural comb, cut directly from top-bar hives or harvested as natural comb from Langstroth hives, into the pressing basket. As you turn the press screw, a plate descends and crushes the comb, forcing honey through a mesh screen at the bottom. The liquid honey drains out while the crushed wax and remaining debris stay behind in the basket.

This method is particularly well-suited for Kenya Top Bar Hives (KTBH), which are popular among small-scale Kenyan beekeepers. KTBH hives produce natural comb without frames or foundation, making them perfect candidates for crush-and-press harvesting. The comb comes out as irregular pieces that wouldn’t work in a centrifugal extractor but press easily.

The Modern Bee Farmers honey press is manually operated, built with food-grade materials, and designed for durability. It requires no electricity, making it practical for rural areas and off-grid beekeeping operations throughout Kenya. The pressing process is straightforward enough for beginners to master quickly.

Advantages of a Honey Press

A honey press requires no structured frames or foundation. This makes it ideal for beekeepers using KTBH hives or those who prefer to harvest comb honey directly. You simply cut the comb from the bars and press it—no frame assembly, no wiring, no foundation sheets to purchase and install.

The operational simplicity is another significant advantage. There’s no need to uncap cells individually or worry about frame positioning. The entire process involves fewer steps: cut comb, load press, turn screw, collect honey. For someone new to beekeeping or managing just a few hives, this straightforward approach reduces the learning curve.

Honey presses cost less than most honey extractor machines and require minimal supporting equipment. You’ll still need strainers to filter out wax particles (more so than with centrifugal extraction), but the overall equipment investment is lower. This makes honey presses accessible for beginners working with limited budgets or those unsure if they want to commit to beekeeping long-term.

For beekeepers who sell comb honey or want to harvest both liquid honey and beeswax in a single operation, a press provides that flexibility. The crushed wax can be cleaned and sold separately, processed into candles or cosmetics, or used to make foundation sheets for other beekeepers.

Limitations of a Honey Press

The major limitation of pressing is that the comb cannot be reused. Once crushed, the wax and comb structure are destroyed. Your bees must rebuild comb from scratch before they can store honey again, which slows down subsequent harvests. This reduction in productivity becomes more significant as your apiary grows or if you want to harvest multiple times per season.

Pressed honey typically contains more wax particles and debris compared to extracted honey. You’ll need to strain it thoroughly, often through multiple sieves, and even then, some fine particles may remain. While this doesn’t affect honey quality or safety, it may impact appearance and marketability, especially if you’re selling to customers who expect crystal-clear liquid honey.

The pressing process is slower than centrifugal extraction, particularly when handling larger volumes. Pressing one batch of comb takes time, you turn the screw gradually to avoid damaging the basket mesh, then wait for honey to drain completely before loading the next batch. For beekeepers managing more than 10-15 hives, this time investment can become impractical during peak harvest periods.

Which Option Fits Your Kenyan Apiary?

The right choice between a honey press and honey extractor machine depends on several key factors specific to your operation:

If you use Langstroth hives and want to maximize productivity through comb reuse, a honey extractor machine makes practical sense. The ability to harvest honey multiple times per season from the same frames increases your overall yield without expanding hive numbers.

If you use Kenya Top Bar Hives (KTBH) exclusively and harvest natural comb, a honey press is the more practical tool. The irregular comb pieces from top bars don’t work in centrifugal extractors, making pressing your most straightforward option.

Budget considerations matter significantly. If you’re starting with limited capital, a honey press provides functional honey harvesting at a lower initial investment. You can always upgrade to an extractor later as your operation grows. However, if you’re committed to commercial beekeeping from the start and have the capital, investing in a quality honey extractor machine sets you up for efficient processing as you scale.

Consider your production scale. For 1-5 hives, either method works, though a press may be more economical. For 6-15 hives, a manual extractor starts making more sense if you use Langstroth frames. For operations with 15+ hives, a 3-frame or 4-frame honey extractor machine becomes increasingly valuable, and electric models start justifying their cost through labor savings.

Labor availability plays a role too. If you harvest infrequently and don’t mind spending extra time processing honey, pressing works fine. If you need to process honey quickly during harvest periods, or if physical labor is a concern, centrifugal extraction (especially electric) reduces effort significantly.

Your market focus might also influence the decision. If you plan to sell comb honey or market raw honeycomb as a premium product, pressing still allows you to harvest some liquid honey while keeping comb sections intact for sale. If you’re focused purely on liquid honey production for maximum volume, extraction is more efficient.

Pricing Overview in Kenya (Based on Modern Bee Farmers Catalogue)

Understanding equipment costs helps you plan your investment properly. Here are the current prices from Modern Bee Farmers in Nairobi:

Honey Press: KSh 24,500

Manual Honey Extractors:

- 2-frame centrifuge extractor: KSh 24,500

- 3-frame centrifuge extractor: KSh 34,500

- 4-frame centrifuge extractor: KSh 55,000

Electric Honey Extractor:

- 4-frame electric extractor: KSh 87,500

Essential Decapping Tools:

- Uncapping fork: KSh 550

- Uncapping knife: KSh 850

- Electric uncapping knife: KSh 2,500

Supporting Equipment:

- Double sieve honey strainer: KSh 3,000

- Conical sieve with hook: KSh 1,500

- 20L food-grade honey bucket: KSh 1,450

- Honey gate valve: KSh 800

Note that the honey press and 2-frame manual extractor are priced identically at KSh 24,500. The main difference in total investment comes from additional equipment—extractors require decapping tools, while presses need more extensive straining equipment to handle the extra wax particles.

When budgeting for extraction, plan for approximately KSh 4,000-6,000 in additional tools (decapping knife, double sieve, buckets) beyond the extractor cost. For pressing, budget around KSh 3,000-5,000 for quality strainers and collection buckets.

Prices may vary slightly and availability should always be confirmed before purchasing, as stock levels fluctuate with demand during harvest seasons

Where to Buy Honey Processing Equipment in Kenya

Modern Bee Farmers is located in Mirema, Zimmerman, Nairobi, and serves beekeepers throughout Kenya and East Africa. They stock the complete range of honey harvesting equipment discussed in this article, including manual and electric honey extractors, honey presses, decapping tools, strainers, settling tanks, and food-grade storage buckets.

We offer delivery services across Kenya, though shipping charges vary depending on location. Before placing orders, it’s advisable to confirm current product availability, especially during peak harvest seasons when demand for extraction equipment is highest.

Contact us directly to discuss your specific beekeeping needs, verify current pricing, and arrange equipment delivery to your location.